Maximize Profitability: The 5 Step Process to Optimize Inventory with Konnektive

Having the right inventory levels is critical for your bottom line.

Yet, the average level of inventory accuracy in the US is just 63 percent. Unfortunately, this may have a negative impact on your revenue, since:

-

Having too low inventory levels. You’re losing on potential sales you could’ve made.

-

Having too high inventory levels. You’re wasting your resources on items that won’t sell.

Both of which drain your resources and make you less efficient.

There are a lot of ways you can manage your inventory. However, we’ve developed a 5 step bulletproof approach we’ve used for over 20+ years of working with ecommerce businesses.

(Saving them thousands in revenue every week!)

In this post, you’ll learn our top-secret 5 step process for optimizing your inventory levels. And how to apply it to your business instantly.

Let’s get started.

#1: Establish an Inventory System

Establishing an inventory system will let you:

-

Track & organize products

-

Ensure optimum stock levels

-

Reduce any waste

…all of which massively boost your revenue and minimize the resources you need to allocate.

To make this process as efficient as possible, you need to conduct a thorough analysis of your current inventory, which includes.

-

Identifying existing stock levels

-

Determining demand patterns

-

Categorizing products

Doing so will help you identify slow-moving items that can be liquidated to free up valuable space.

Once you have a clear understanding of your inventory, it's time to integrate a reliable inventory management software.

This software can automate tracking stock levels or providing insights on product performance.

With a centralized system in place, you can monitor inventory levels across various locations, making it easier to maintain optimum stock levels and prevent stockouts.

Another important aspect of inventory management is setting up a reliable purchasing process.

This involves establishing relationships with suppliers, negotiating favorable terms, and implementing a system for reorder point and economic order quantity calculations.

By replenishing stock only when necessary and in the right quantities, you can avoid excess inventory.

Regularly monitoring and analyzing inventory data is crucial for making informed decisions and avoiding stock-related issues. You can easily identify trends and optimize your inventory management system through tracking key performance indicators such as:

-

Lead time

-

Stock turnover rate

-

Customer demand patterns

This will ensure you always have the right products available for your customers.

…leading to increased customer satisfaction and business growth.

#2: Track Inventory Levels

One of the primary goals of effective inventory management is to strike a balance between supply and demand – or else you’re having too high expenses or losing sales..

(Both of which are not optimal and lead to lower revenue.)

To track inventory levels accurately, businesses can employ various methods.

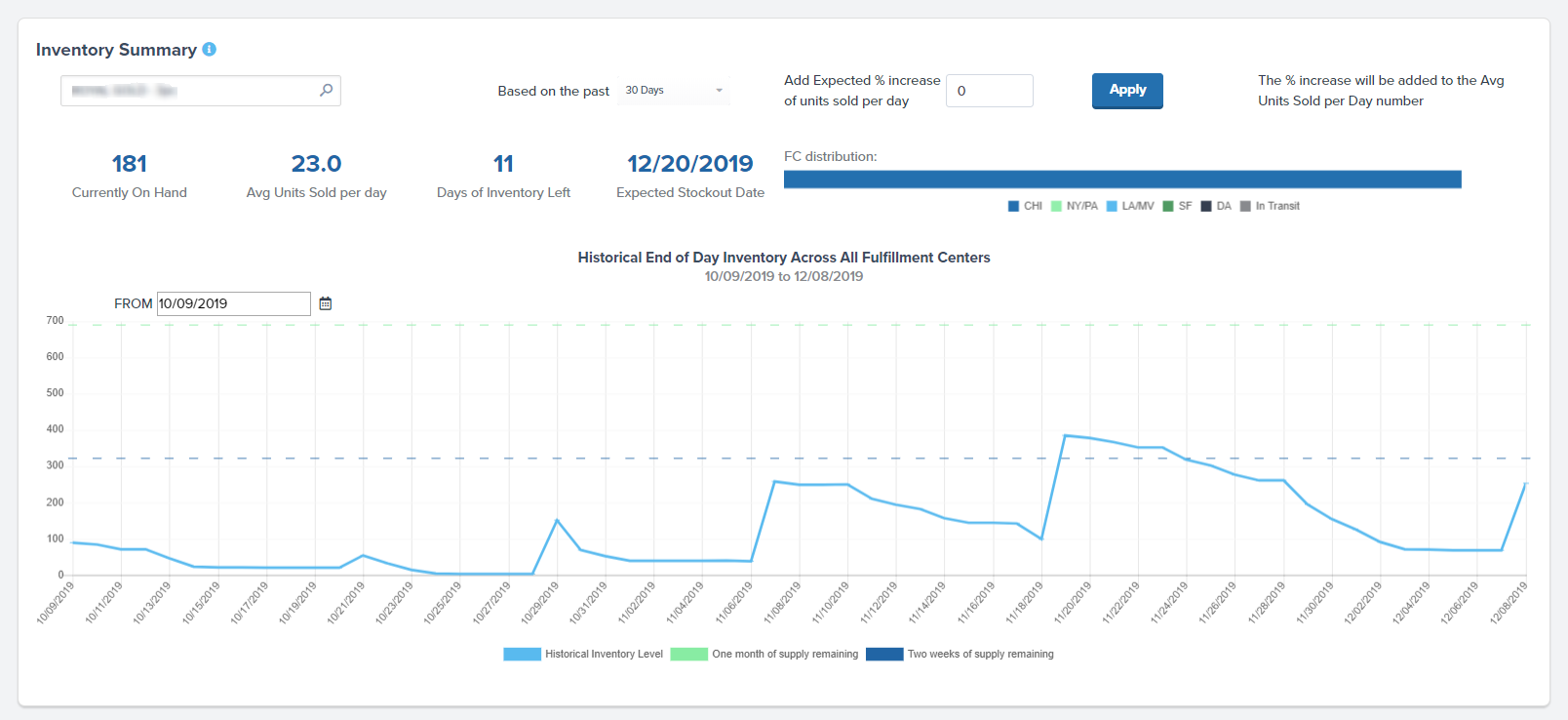

The most common approach is using inventory management software that integrates with other business systems, such as point-of-sale systems and procurement.

This software enables you to monitor real-time inventory levels, assess sales patterns, and plan for future demand. By having an understanding of inventory status, you are in a better position to make the right decisions regarding reordering, promotions, or discounts.

Another critical thing is implementing proper inventory control measures.

This involves setting up appropriate policies and procedures to track the movement of inventory, prevent theft or loss, and ensure accurate stocktaking.

Regular inventory counts or cycle counts can help businesses identify discrepancies and take corrective measures promptly. Additionally, adopting a just-in-time (JIT) inventory approach can minimize storage costs by only replenishing stock as needed and relying on efficient supply chain management.

#3: Monitor Supplier Orders

Monitoring supplier orders involves keeping a close eye on the orders placed with various suppliers.

It entails tracking the progress of these orders, from the moment they are placed until they are delivered to your doorstep.

By effectively monitoring supplier orders, you can ensure:

-

Minimize the risk of overstocking

-

Smooth supply chain operation

-

Avoid stock-outs

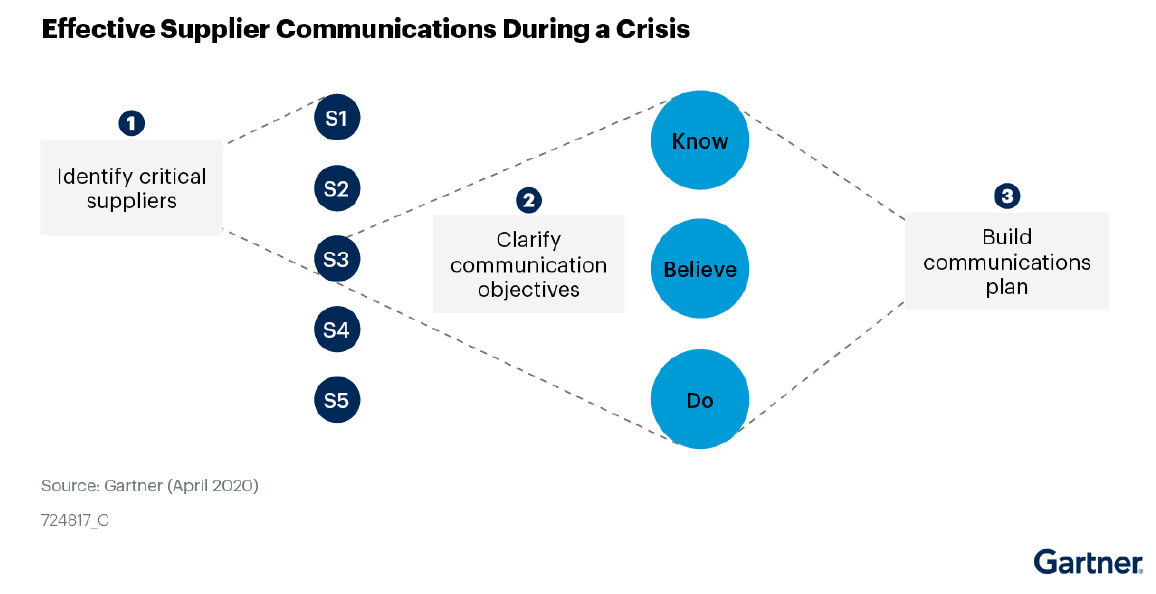

The first step in monitoring supplier orders is to establish clear communication with suppliers.

This allows businesses to stay informed about the status of their orders, including any delays or issues that may arise.

Doing so enables businesses to proactively address any potential problems and find solutions.

We’ve talked about automation and inventory management tools before. However, it does not stop there and you should leverage technology to efficiently monitor supplier orders too.

Implementing inventory management software, for instance, provides businesses with real-time visibility into their orders. This allows you to track shipments, receive notifications about any changes in delivery schedules, and accurately forecast the arrival of inventory.

By automating these processes, you can effectively achieve:

-

Saving time and resources

-

Reducing the chances of human error

-

Ensuring smoother inventory management

Furthermore, analyzing historical data can provide valuable insights into supplier performance.

Monitoring the timeliness and accuracy of past deliveries allows businesses to discern patterns and make informed decisions regarding their supplier relationships. Having this information empowers you to choose reliable suppliers who consistently meet delivery deadlines, minimizing disruptions to their inventory management.

#4: Calculate Reorder Points

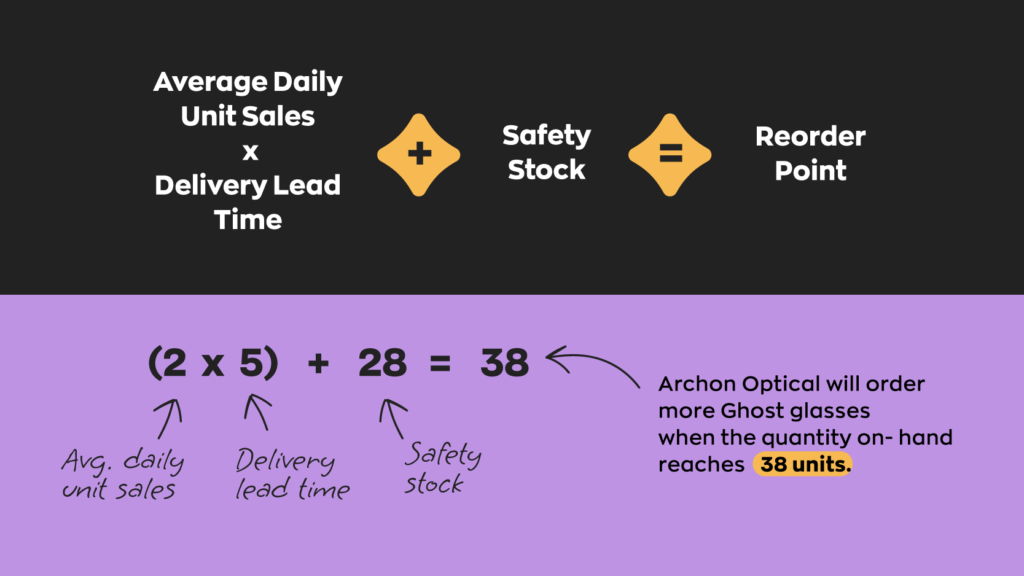

The reorder point is the inventory level at which a new order needs to be placed to replenish the stock before it runs out.

It helps businesses avoid stockouts, which can lead to lost sales and dissatisfied customers.

(Having a huge negative impact on customers.)

Calculating the reorder point involves considering various factors such as lead time, demand, and safety stock. To calculate the reorder point, businesses need to know the average daily usage of the product and the lead time of the supplier.

The lead time is the time it takes for the supplier to deliver the ordered items.

By multiplying the average daily usage by the lead time, businesses can determine the quantity of stock that needs to be replenished to meet the demand during the lead time.

Another factor to consider is the variability in demand during the lead time.

This is where safety stock comes into play. Safety stock is an extra amount of inventory kept to cover unexpected fluctuations in demand or delays in delivery. By adding the safety stock to the reorder point, businesses can ensure a buffer to cope with unexpected circumstances and prevent stockouts.

Moreover, technology has made it easier than ever to calculate reorder points accurately.

Many inventory management software solutions are available that can automatically calculate reorder points based on historical data, sales forecasts, and lead times.

These tools provide businesses with real-time visibility into their inventory levels.

(allowing for efficient ordering and minimizing the risk of excess stock.)

#5: Develop an Organization System

Developing an organization system for inventory management is essential to maintain control and maximize efficiency.

One of the first steps is to categorize and classify the inventory items based on their characteristics:

-

Size

-

Type

-

Usage

This allows businesses to create a logical structure that makes it easier to navigate through the inventory and find specific items quickly.

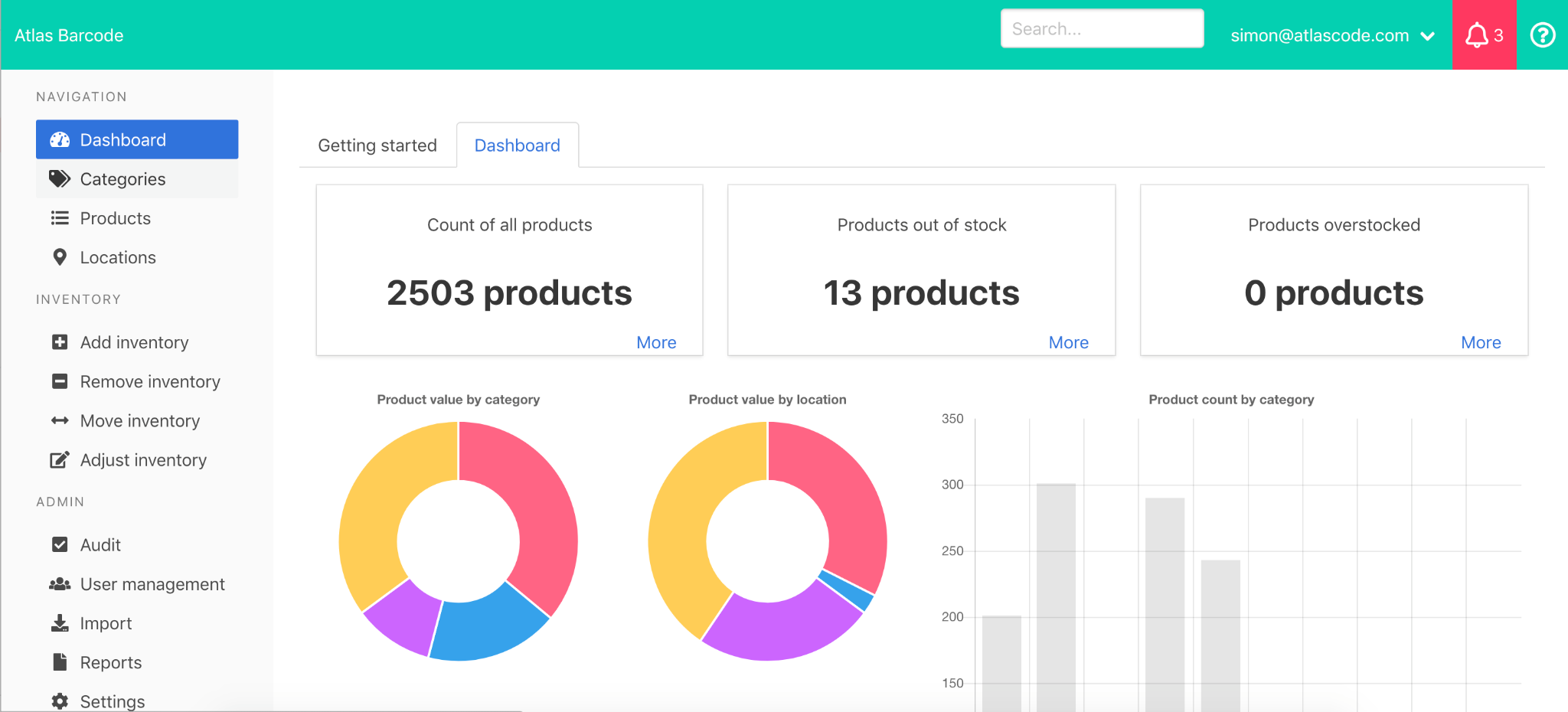

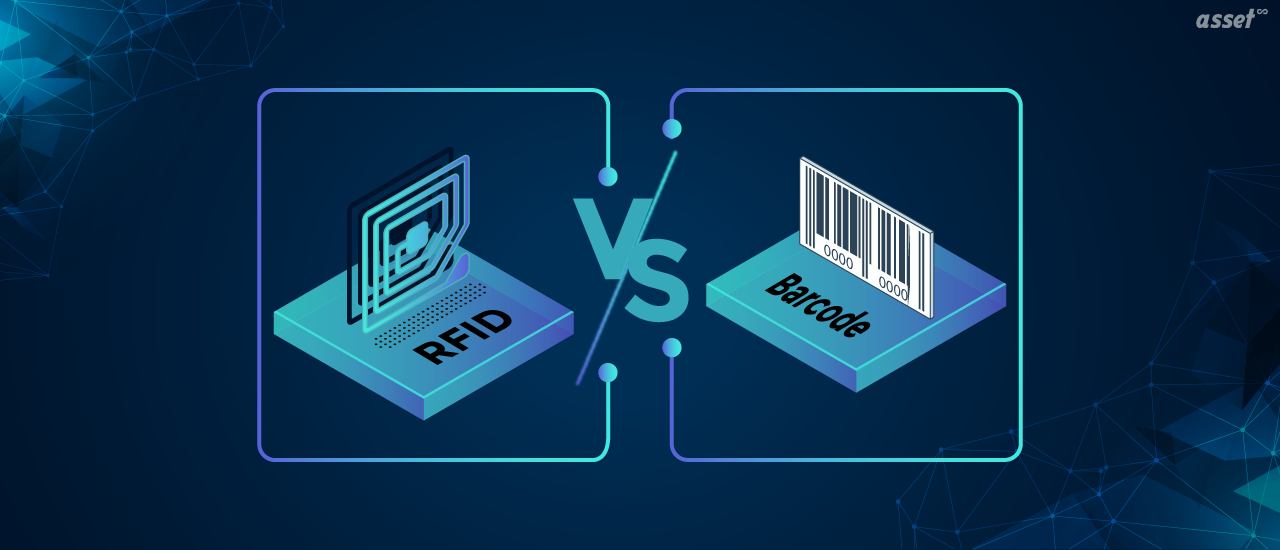

Plus, implementing a barcode or RFID system can greatly enhance inventory tracking accuracy.

By attaching unique identifiers to each item, businesses can easily scan and update inventory status in real-time, minimizing human error and enabling timely replenishment when necessary.

Having such system in place also provides you:

-

valuable insights into demand patterns

-

Helping businesses forecast sales

-

Maintain optimal stock levels

Having clear and accurate documentation is another crucial aspect of inventory organization.

This includes maintaining up-to-date records of each item's description, quantity, cost, and supplier information. By regularly updating these records, you can have an overview of an inventory and make the right decisions regarding:

-

Future purchasing strategies

-

Stock replenishment

-

Pricing

Also, regular audits and inventory counts are necessary to ensure the accuracy of stock levels and identify any discrepancies or potential issues.

For instance, you can implement cycle counting – an inventory counting method.

It’s a method where a small portion of the inventory is counted at regular intervals, and can help in maintaining accurate stock records without disrupting regular operations. This way, businesses can proactively address any inventory discrepancies, minimize losses, and maintain an efficient and organized system.

Drive Revenue & Maximize Profitability

Inventory management plays a critical role in driving revenue and minimizing wasted resources. You now know precisely how to manage your inventory and maximize profitability.

If you’re looking for additional ways to make your business more profitable, check these resources:

To be as efficient as possible with your inventory, you need to use the newest technologies.

That’s precisely what Konnektive CRM can help you with. Konnektive CRM provides you with detailed statistics about your customers, inventory, and orders. That way, you can always keep your stock at the right levels, and never lose a single sale!

Book a free demo with us and reduce your customer retention cost right now.